Inventory Optimization Pieces that Disable Your Success

Inventory Optimization: Balance is Key for a Success

How can you ensure the highest levels of success? Merchandisers and Buyers are executing promotions, product assortment changes, and new product roll-out events throughout the year. Those events affect the flow of product into your DCs and stores. They can also affect vendor fill rates and lead time performance. The volume of product purchased from a vendor also changes with those events. Unless you monitor and adjust to those changes, you will lose margin and sales. Inventory Optimization solutions provide value by monitoring the on time performance and volumes of your suppliers and allow you to make adjustments along the way.

Inventory Optimization Improves Overall Productivity and Efficiency

Inventory Optimization is a strategic part of the buying role that many companies don’t realize today. The truth: Buying that is based on accurate demand forecasting, accurate lead time forecasting and effective balancing of acquisition and carry costs against gross margin over time delivers significantly higher gross margins, better GMROI, fewer ‘exception management’ alerts and balanced inventory levels.

“Read more about inventory optimization, a Top Blog of 2013 here: The Truth About Inventory Optimization Show Me The Money

On the same page with the blog, download a free inventory optimization kit.

If you are looking to improve performance, optimization is the key to success. It analyzes demand and cost information to provide you with buying decisions that are based on finding best buy quantities and guarantees you the lowest product costs and highest possible margins. Lead time optimization delivers higher on time performance; providing higher fill rates for your suppliers and higher customer satisfaction. If you vendor has seasonal performance issues, the optimization engine adjusts lead time to compensate. Inventory Optimization and Lead Time Optimization are key tools for successful trade promotions and raising your profitability.

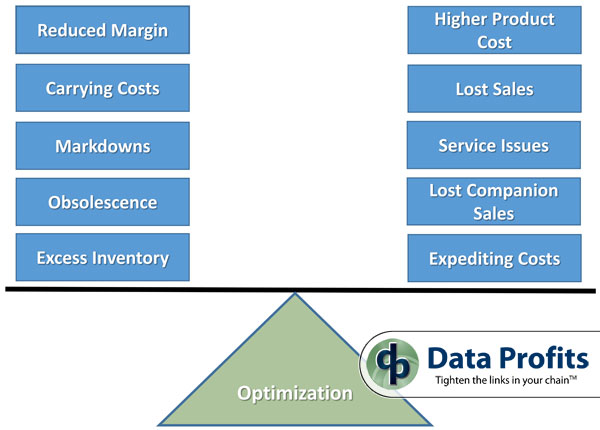

Inventory Optimization requires a careful Balancing Act

Inventory Optimization requires a careful balancing act to take place between the economies of scale that vendors and carriers offer against your cost of buying and holding goods at the warehouse and store level. To gain maximum benefit the balancing act needs to take place regularly on an automated basis without having to use the square root equation in Excel!

Here’s some of the key performance pieces that inventory optimization touches on:

Inventory Optimization provides Real World Results

Optimization is a powerful tool for wholesalers and retailers. It provides lower inventory levels and lowers product costs while supporting higher customer satisfaction and growing profits. By balancing all of the cost factors while understanding vendor performance and customer demand, optimization is a powerful tool for today’s forward thinking retailers.

How Do You Combine and Analyze all the Inventory Optimization Data and Also Make It Easily Visible?

You need a good software solution to manage the data and math, this is not place for excel. You also need a clean simple way to display the results in an effective format. Visit our website to learn more about managing your Inventory Optimization pieces. Also you can contact Us. to help you find a balanced solution for your business’ inventory challenges. We’ll help you ‘Tighten the Links in Your Chain™.’

Copyright © Data Profits, Inc. 2014 All Rights Reserved.

- How to Avoid Carrying Cost Mistakes in Inventory Optimization - June 10, 2024

- 3 Common Forecasting Software Issues and How to Fix - May 20, 2024

- The Hidden Connection: Lead Time And Inventory Optimization Explained - May 13, 2024