3 Tricks to Fix the Bullwhip Effect and Smooth Inventory Replenishment

A Bullwhip Effect Creates Waves of Inventory Issues

Demand forecasting can eliminate many of your “wave-riding” activities in supply chain planning. Your company invests significant resources, time, and money in planning and executing inventory replenishment and promotional events. You often experience service problems when your suppliers don’t have inventory to support your business. The suppliers operate their supply chain independently of yours and forecast demand from your purchase orders. This sales forecasting approach has a silo effect on information; your partners don’t get an accurate view of the end consumer’s demand. When do suppliers see order quantities changing, up or down; how do they interpret the signal? Sometimes, they view changes as trends or lumpy demand and react by changing their production or inventory plans. This results in a wave of overreaction called the “bullwhip effect.”

Are your Demand Planners Wave-Riders? Eliminate the Bullwhip Effect

Suppliers don’t view the actual customer demand; they react to PO quantities with their adjustments to make/buy decisions, which can create overstocks or out of stocks. The demand signal becomes more magnified as the signal moves upstream at each level of the supply chain. Since the repeating waves or curve is reminiscent of a cracking whip, it became known as the “bullwhip effect.” By embracing demand forecasting & collaboration with suppliers, you can provide an End-to-End view. Eliminating the “bullwhip” that sales forecasting “misinformation” causes will lower product costs and improve fill rates.

University studies identified the Bullwhip 50 years ago. Here are two studies that I think you’ll enjoy:

Why did P&G have supply chain issues with Pampers? Proctor and Gamble’s had problems with fill rates and product costs. The consultants took a look at the Pampers supply chain and were surprised by the results: Diaper usage was fairly constant, the babies were doing their job, but the supply chain was creating its own set of problems. Click to read more.

Volvo cornered the market on green sedans. Why? The green cars weren’t selling, so Volvo USA created some dealer incentives. The incentives worked so well, that their Swedish production planners made even more. Click to read more.

A Simple Fact: The Farther from Consumers, the Greater the Wave

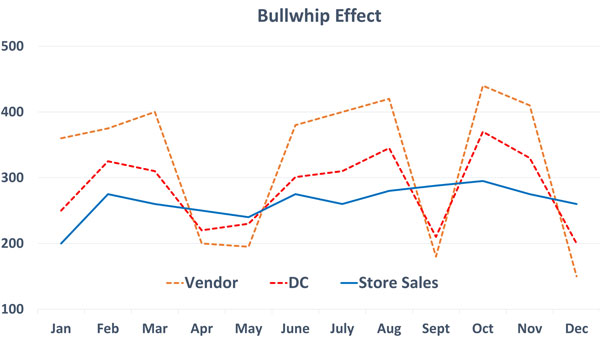

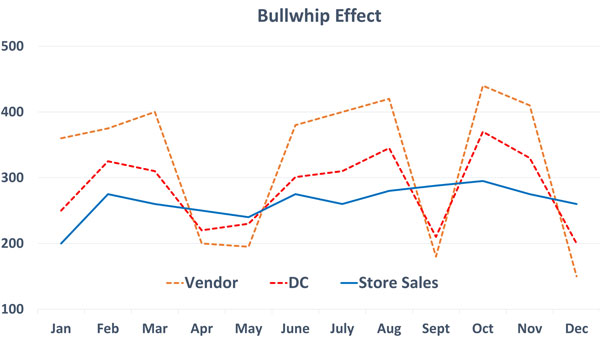

In the graph below, note that the further the inventory partners (DC, Vendor) are from the consumer sales, the more significant each partner’s reaction to events. Look at March, and note how the store sales are about 250. The vendor’s response is to ship 400, scrambling to build more inventory. This isn’t a time-phased response by the vendor to future customer orders; it is a resulting bullwhip effect. Also note that, like cracking a real bullwhip, the supply curves are repeating waves.

In periods of rising demand, the store level of a supply chain increases its orders. With periods of lower demand, the lower levels of a supply chain will order less or stop ordering; see April & Sept. The wave effect is amplified as you move up the supply chain from consumer to retail store to distributor to manufacturer.

How can you change the game?

By using more accurate demand forecasting and collaborating with your suppliers, eliminating the silos of information and the bullwhip! Click here to read more about Inventory Optimization and the Bullwhip Effect.

3 Steps to Take to Eliminate the Bullwhip

- Utilize Demand Forecasting Methodology, not Sales Forecasting. Demand forecasting software considers events such as promotions, lost sales, and markdowns and cleans up dirty data. To read a popular blog about the improvements demand forecasting provides beyond sales forecasting, click here.

- Store and DC Inventory Replenishment needs to be based on Demand Forecasting. Here is a current blog outlining the benefits of demand driven inventory replenishment.

- Share Demand Forecasts and Order Projections with Suppliers. End-to-end collaboration needs to happen every day to maximize results. Providing web access to your demand forecasts, future order projections, and promotion scorecards is a win-win. Better information can lower costs, provide shorter lead times, and drive higher fill rates, driving better results.

Sharing store-level signals and promotion activities across your supply chain can have a large impact on your bottom line. Subscribe to our blog; we’ll be covering end-to-end collaboration soon.

Time for a Demand Driven Journey

If your legacy software lacks these capabilities, you need to consider new options. Modern software can eliminate a major cause of daily “wave surfing” and greatly improve your supply chain’s performance. Not doing these things costs a lot more than implementing cloud-based software.

Are You Fighting the Waves of the Bullwhip Effect?

Contact us for more information on identifying and dealing with the bullwhip effect. We’re here to help you Tighten the Links in Your Chain™.

Copyright © Data Profits, Inc. 2014 All Rights Reserved.

- How to Avoid Carrying Cost Mistakes in Inventory Optimization - June 10, 2024

- 3 Common Forecasting Software Issues and How to Fix - May 20, 2024

- The Hidden Connection: Lead Time And Inventory Optimization Explained - May 13, 2024