The Unseen Biggest Dangers of Lost Sales

Lost Sales are just a KPI, Right?!?

Lost sales are a perpetual worry for all retailers. If your shelves are empty, customers go home empty-handed, and you won’t make your sales plan. Most replenishment systems and demand forecasting systems offer a lost sales calculation to help retailers manage this key business problem. But is your lost sales calculation actually helping you as much as you thought? Are you still watching sales slip through your fingers and wondering why?

But I Have a Lost Sales Report!

The key is how your replenishment system or demand forecasting system treats lost sales. The vast majority of popular systems treat lost sales as a Key Performance Indicator (KPI). It’s calculated, recorded, and reported on but that’s where it stops. The lost sales never figure into the forecast as demand. That means while you feel good about having a report of your lost sales, you are still losing sales.

Lost Sales as a KPI

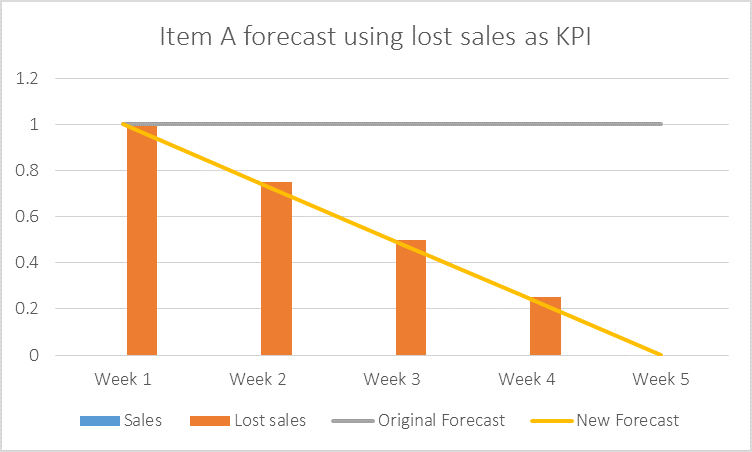

Let’s look at an example. Item A sells one unit per week every week all year long like clockwork. Your demand forecast is one per week. The supplier has a fire, and suddenly Item A is not available for a month. So for Week 1, you are out of stock with a forecast of one unit. The system records one lost sale just like it is designed to do, but the system ignores that lost sale when it reforecasts at the end of the week. Now your forecast for week 2 is 0.75. Week 2 you are out of stock. The system records lost sales of 0.75, but at the end of the week, again the forecast is lowered. This keeps happening until your forecast is 0. It might look like this:

Let’s look at an example. Item A sells one unit per week every week all year long like clockwork. Your demand forecast is one per week. The supplier has a fire, and suddenly Item A is not available for a month. So for Week 1, you are out of stock with a forecast of one unit. The system records one lost sale just like it is designed to do, but the system ignores that lost sale when it reforecasts at the end of the week. Now your forecast for week 2 is 0.75. Week 2 you are out of stock. The system records lost sales of 0.75, but at the end of the week, again the forecast is lowered. This keeps happening until your forecast is 0. It might look like this:

So your forecast of 52 per year has suddenly dwindled to 0. Guess what happens when the item is available again? More outs and more lost sales until finally the system catches up or you step in to make a manual change. You might chase it for weeks. Next year, you might repeat the outs all over again because you have no demand history. Now you have lost sales three times over!

Lost Sales as Demand

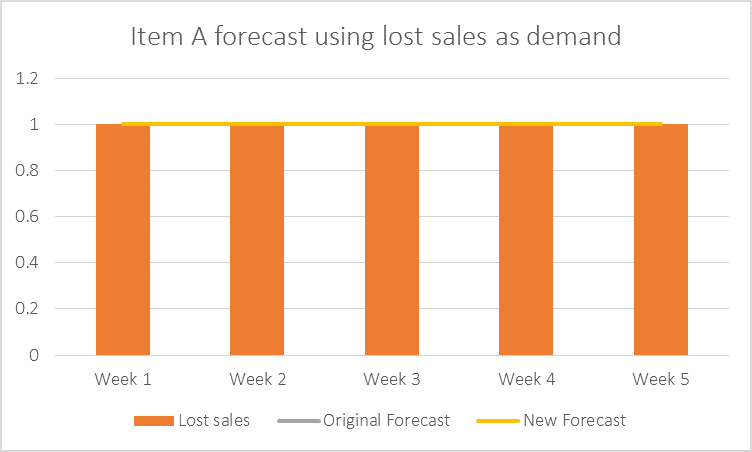

But what if your system used those lost sales as part of the demand forecast calculation? When it reforecasts at the end of Week 1, it keeps the forecast for Week 2 at one. When it reforecasts at the end of Week 2, the forecast stays at one. No matter how long you are out of stock, the system figures the lost sales as if they were sales and your forecast for the year stays at 52. It would look like this:

When Item A starts shipping again, your system is ready to keep up with sales with no manual interventions needed. Next year, you don’t even notice because the lost sales are providing the demand history. What used to be weeks of babysitting is now barely a bump in the road. Such a small change, but such a big impact.

Common Sense is Not So Common

The second example is what most of us would prefer to happen. But you would be shocked how many popular demand forecasting and replenishment systems operate just like the first example. They report lost sales but don’t do much else with them, resulting in more lost sales. Yours might be one of them. Want to start forecasting demand on lost sales and tighten this link in your chain? Learn More

Copyright © Data Profits, Inc. 2015 All Rights Reserved.

- How to Avoid Carrying Cost Mistakes in Inventory Optimization - June 10, 2024

- 3 Common Forecasting Software Issues and How to Fix - May 20, 2024

- The Hidden Connection: Lead Time And Inventory Optimization Explained - May 13, 2024